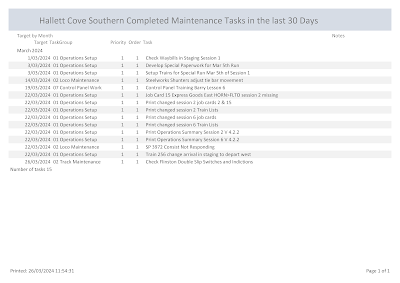

This month's activities have included GoPro Filming, Planning for Paolo, Control Panel Training, Ops Session, Tasks Completed in last 30 days & Scheduled Tasks for next 90 days.

GoPro Filming

I arranged for Ross to bring his car fitted with a GoPro camera over to film parts of the layout. Ross and his wife were coming over for a few hours on Friday 22nd at 2:00pm. Well a grass fire started close by and we had 30+ fire trucks and 6 aircraft attacking the fire which approached the end our street. I had to ask Ross not to come whilst he was enroute!

I took some video of what happened.

I produced some Pdf files of the trackwork in AnyRail for Paolo to print out assemble and place on the benchwork to ensure it meets his needs and expectations. He started the process....

Paolo now has the task of reviewing the track plan to confirm the mainline goes where he wants it. Further he needs to consider if the industry locations and track arrangement suits what he desires to achieve. I am sure much tweaking will be required.

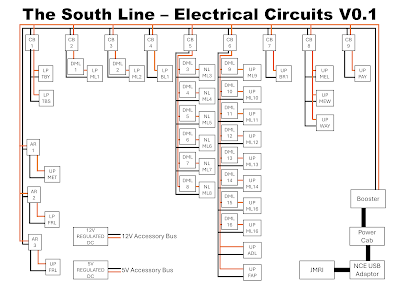

I made a visit to see Paolo's layout in person and am quite confident that the mainline is "mostly" sorted and he new has some "tweaking" on the rest. I have moved on to the electrical design for track power delivery and detection. Here is the preliminary design.

Having the electrical and detection outlined I then looked at his intended basic signalling. Signal nomenclatureSU-xx designates UP trains (Trains heading for Adelaide) and SD-xx Down trains (Trains heading for Tailem Bend).

I then had my first cut at what the "Input States" are needed in order to set "Output States") Signal Indications (Red, Yellow & Green).

|

| Down Trains |

|

| Up Trains |

I'm sure Paolo will need a face to face explanation!

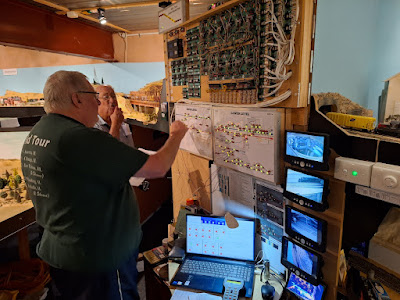

Control Panel Training

Barry requested revision and practice on the Upper Level so this was done during Lesson 6. He has agreed to run the panel with me mentoring on 8th April so we have two more training sessions between now and then,

My Ops Sessions

4th March

The second session for 2024 was held on 4th March. We only had had a small group of operators available, 4 of 7. In the past I would have cancelled the session however this year I have decided to go ahead which means adjustments to the paperwork to accommodate reduced operations. In this case to have trains prepositioned for the next session meant a total rewrite the Running Schedule, Train Graph & Job Cards . Everyone got to run some trains they had either never done of did "a long time ago". We managed to complete all but one movement. We had some fun and that is what matters.

I forgot to take some photos so only one from afternoon tea following the session.

|

| L>R Denis, Peter S, John & Barry |

20th March

My 3rd Wednesday group had a fun session and we ran most of the program. Peter R from Victoria is coming over to stay so we will finish the outstanding stuff before the next operating session. This will bring back some familiarity for Peter prior to him participating in my next Ops Session on 8th April.

|

| L>R Alex, Ross, Me, John, Peter S & Denis |

|

| L>R Alex, Ross, Peter J, John, Peter S & Denis |

|

Afterwards we enjoyed afternoon tea.

Wayne's Ops Session

The first session for the year at Wayne's was held on 29th February. Barry, Denis, Peter S and I attended. We were 1 operator down but ran all but 1 of the scheduled trains. We all had some fun despite the high humidity.

|

| L>R Wayne, Denis, Peter S & Barry |

Here is a video of some running...

Scheduled Tasks for next 90 days

That's it for now so until next time.....

-ooOOOoo-

.png)

.png)

.png)

.png)